Ro Plant Design Calculation Excel

Ro plant design calculation excel. Design of Gravity Main. Reverse Osmosis RO technology has undergone rapid transition. We have increased the output to 3500 m 3 per regeneration by increasing the run length to 26 hours instead of the design 20 hours.

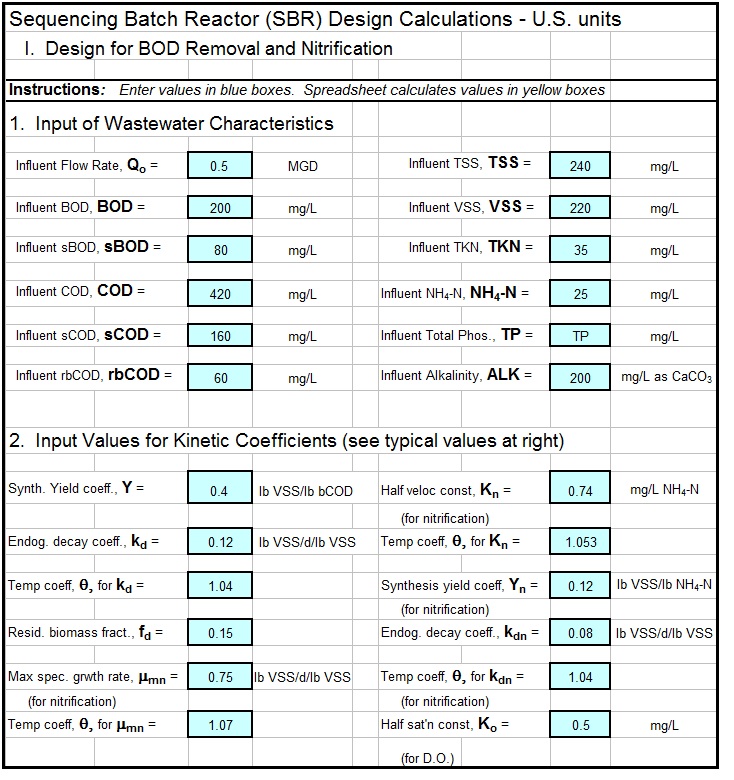

This spreadsheet includes the following calcualtions. From the early days when cellulose acetate membranes were used. Select the design flux GFD or lm 2 h based on pilot data customer experience or the typical design fluxes according to the feed source Step 5.

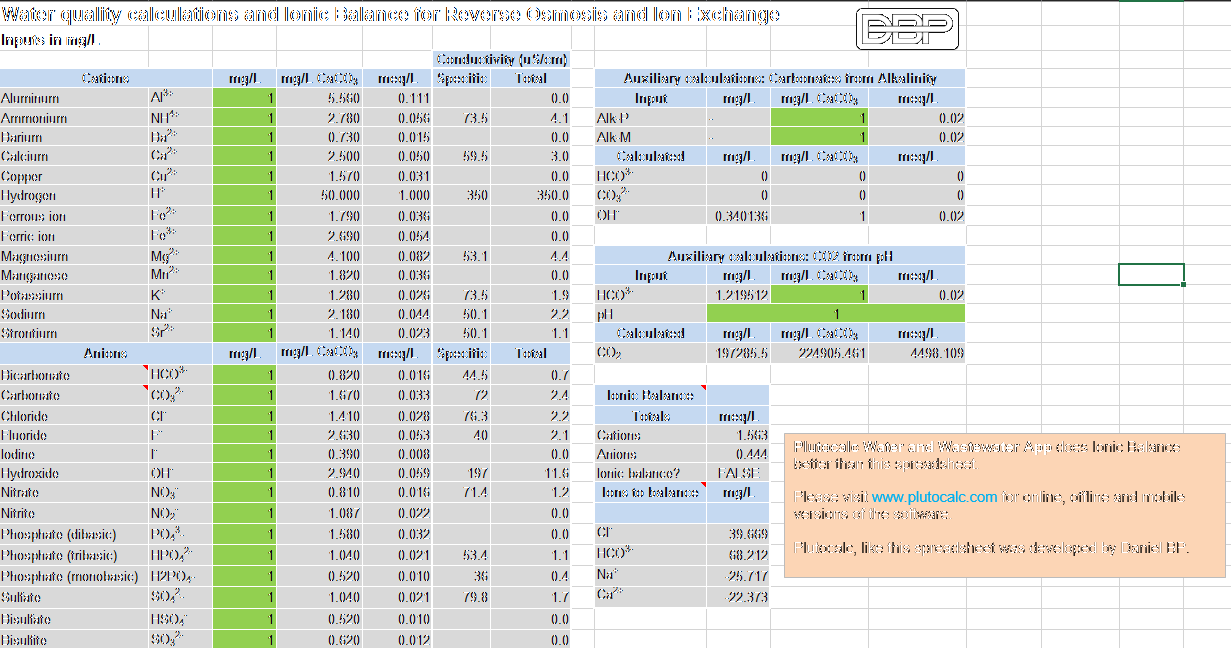

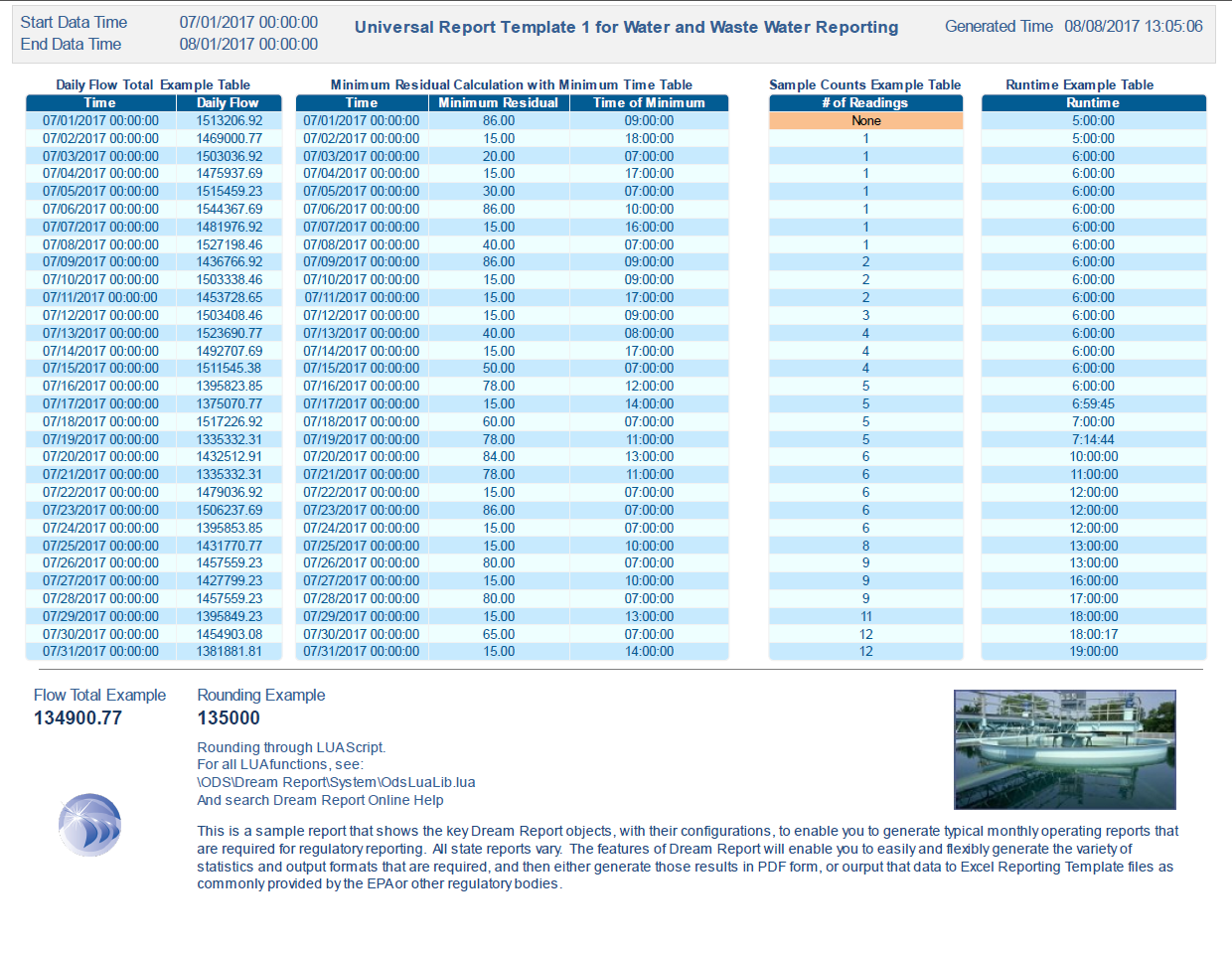

Water standards physical and chemical. The Total Flux and Scaling Program TFSP written for Excel 97 and above provides designers and operators new tools to predict membrane system performance including scaling and. Comparison of Given Data.

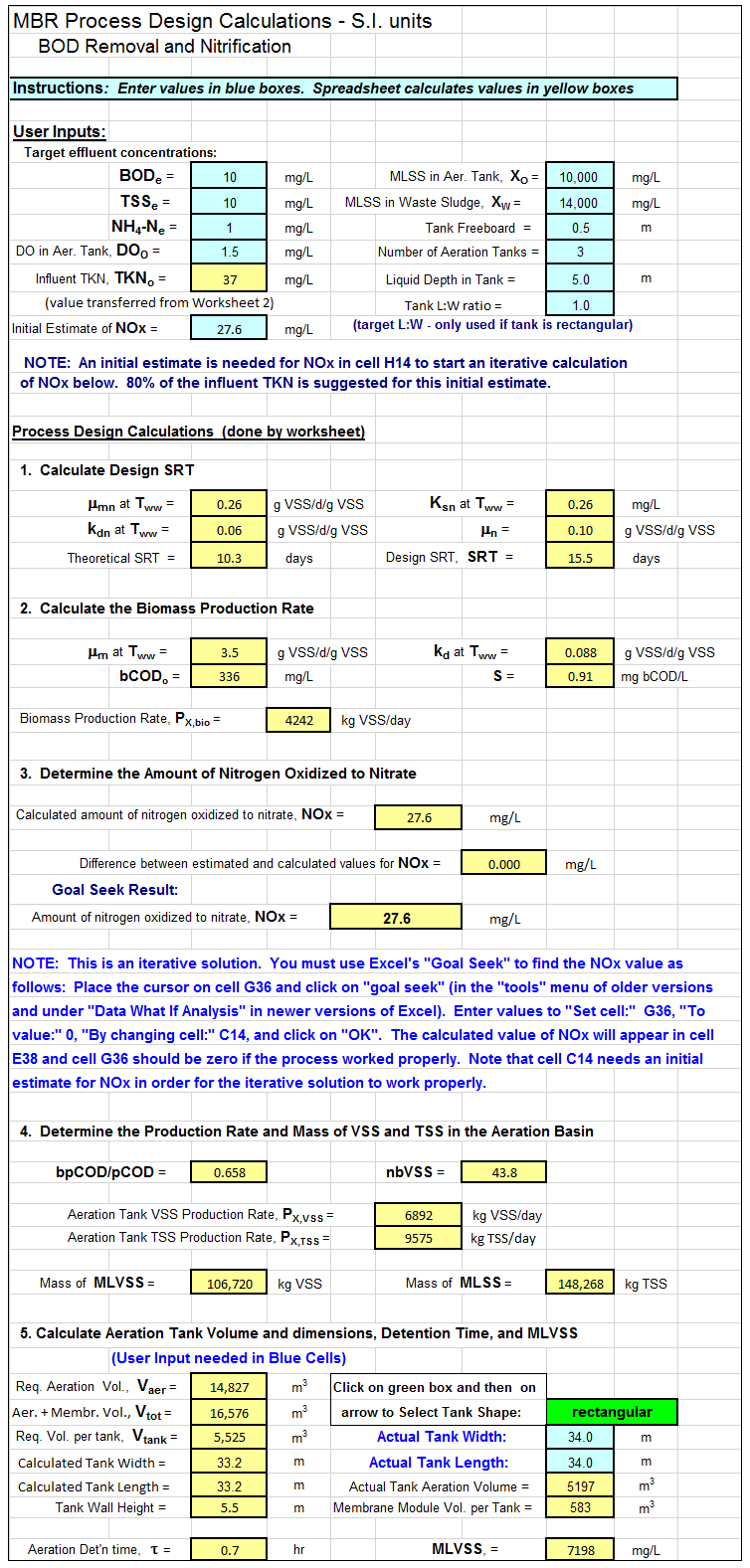

Calculations for trickling filter nrc formula in excel treatment plant design calculations Design Guidline For Small Waste Water Treatment Works June 22nd 2018 - In This Manual The Best Appropriate Process For Such Small Waste Water Treatment Plants Has Already Been Identified As The Rotating Biological Contactors. We are operating DM plant of 2 streams of capacity 2740 m 3 OBR 137 m 3 hr 20 hrs. To accurately measure the performance of an RO system you need the following operation parameters at a minimum.

OBR output between regenerations. It takes a lot of skill to design small commercial RO systems. 71537 Product Flow m3d.

Users can now design systems with concentrate stream recycle simultaneously from Pass 2 to Pass 1 and 2. This method is based on the application of maximum available recovery without scaling of any of the compounds present in the water as silica calcium carbonate calcium sulfate barium sulfate strontium sulfate and calcium fluoride and membrane. Feed Raw Water Characteristics Feed water quality has a significant impact on the design of the RO membrane system.

Selected DP Capacity lh. Presently our ionic load is lower by 40 than design.

28 Chemical consumption-per stream Chemical Consumptionstream Function Chemicals Dosed in the unit operation Use Form Solution Conc.

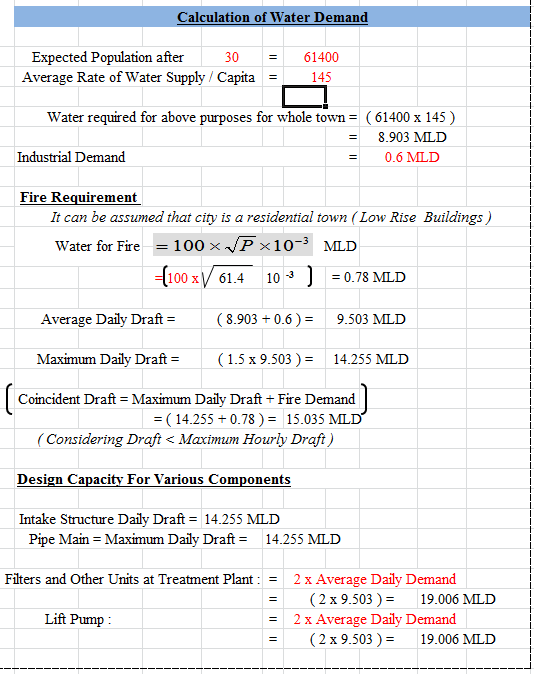

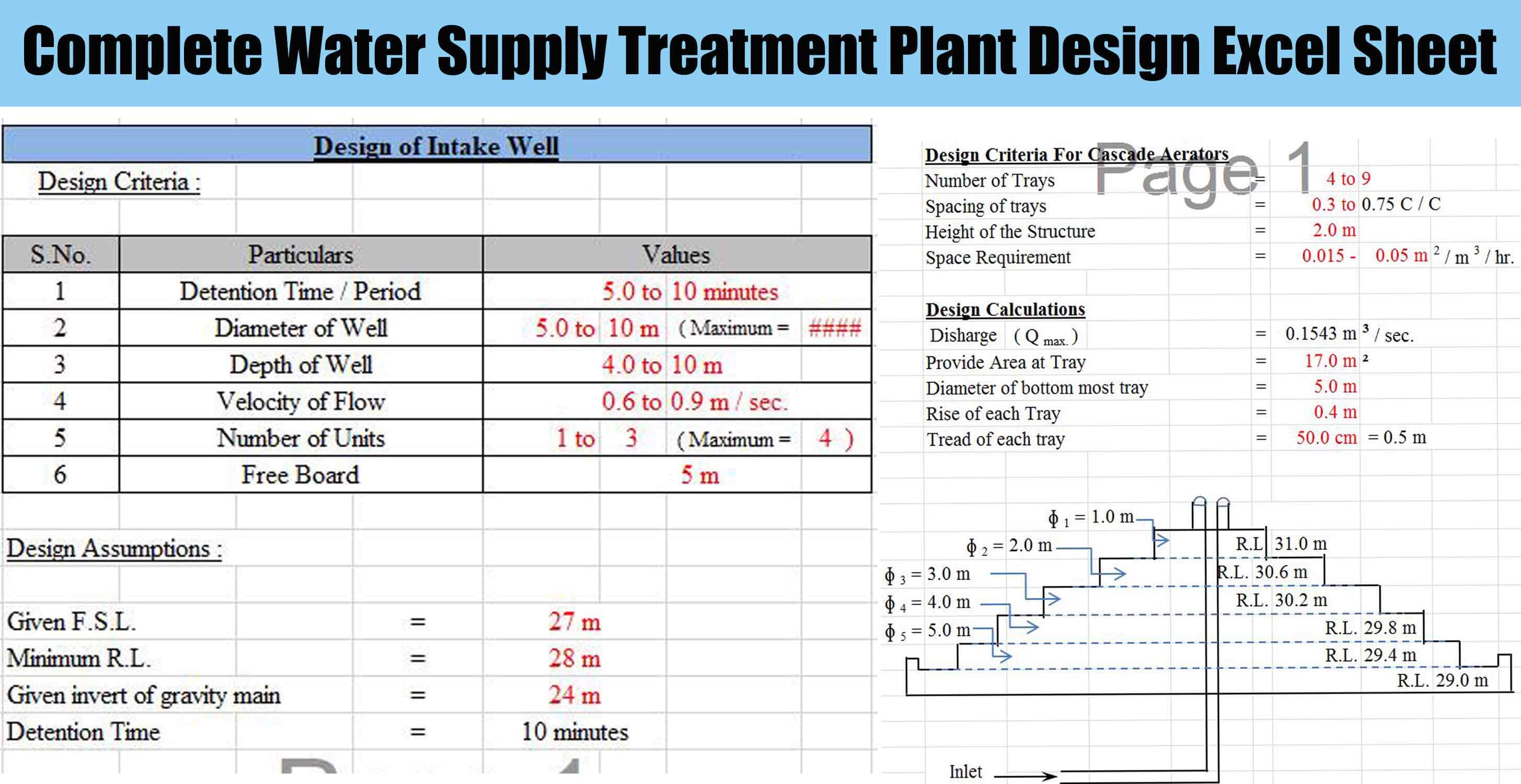

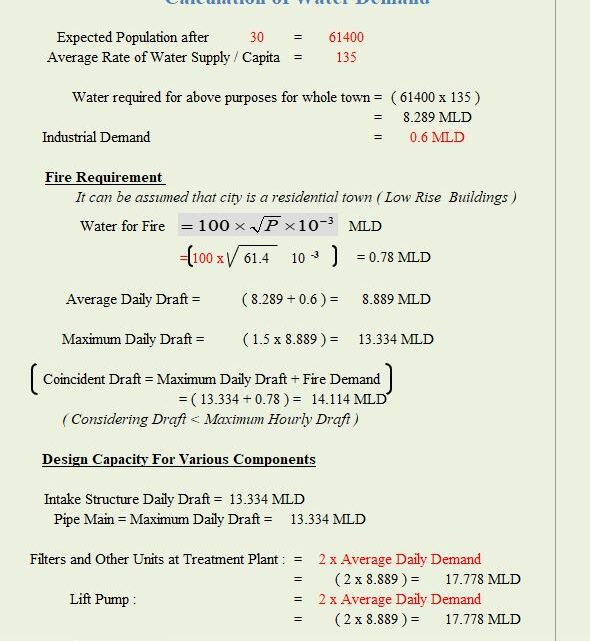

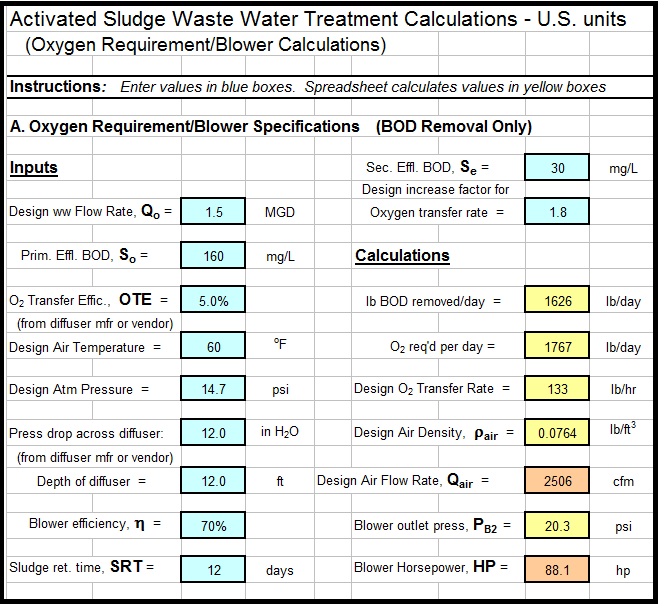

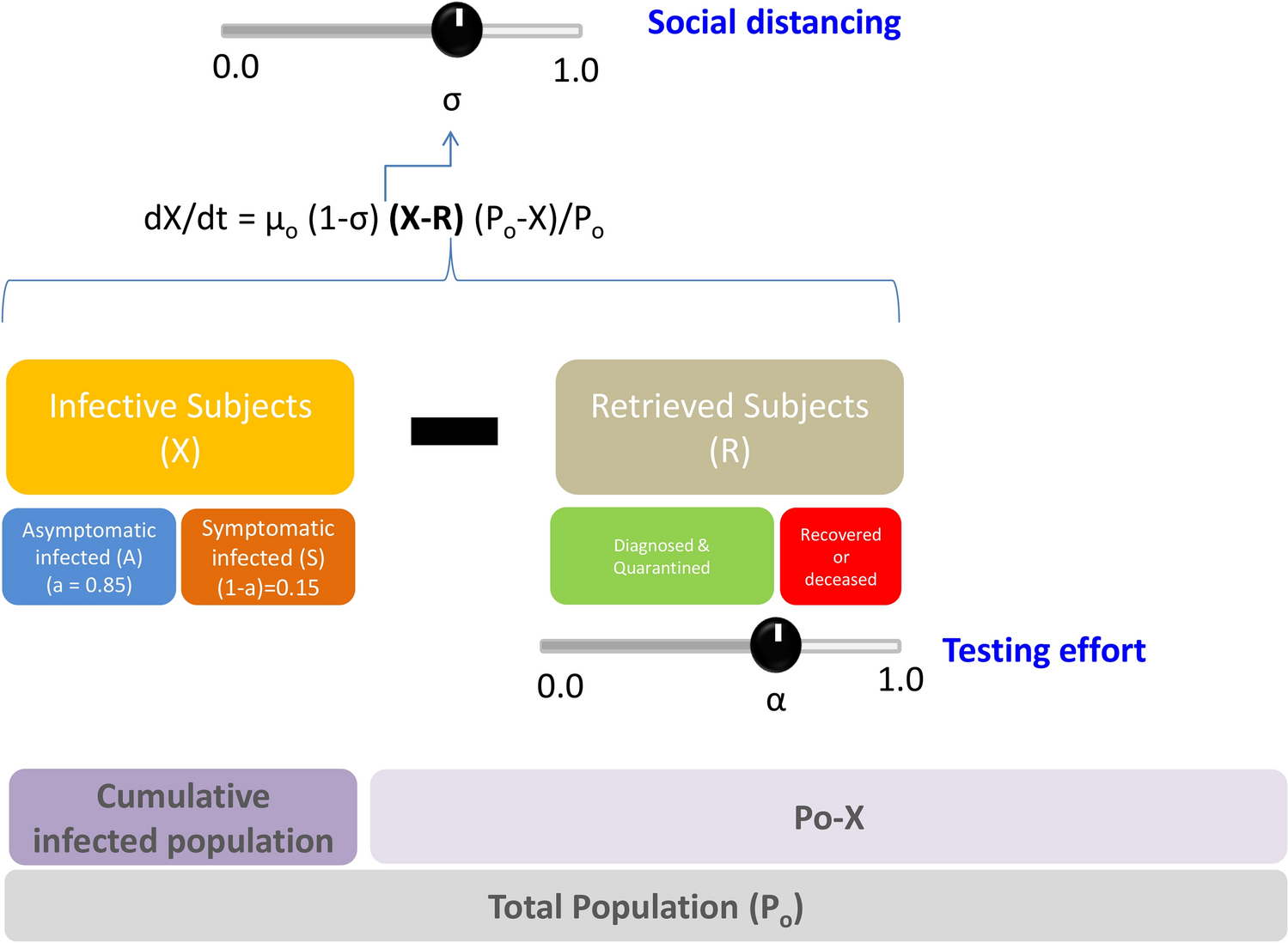

This paper proposes a simple design method of the RO system in RO brackish water desalination plants. BWRO Plant Al Radwa. All calculations are made using a Microsoft EXCEL-based spreadsheet. Flow kgday SG Flow lh KgDay Kg. Select the design flux GFD or lm 2 h based on pilot data customer experience or the typical design fluxes according to the feed source Step 5. Design of Intake Well. An RO system has instrumentation that displays quality flow pressure and sometimes other data like temperature or hours of operation. Chemical Calculation for RO Plant Here is where the rubber meets the road and a little bit of simple maths is required. From the early days when cellulose acetate membranes were used.

Design of Jack Well. This transition process has caused signification transformation and consolidation in membrane chemistry module design and RO plant configuration and operation. Tank size gallon Chemical. Calculate the Number of Elements Needed. Email protected Ro plant design calculation excel how much the molecule weighs to complete these calculations 1 1. Wastewater Treatment Plant Design Calculations Excel. This paper proposes a simple design method of the RO system in RO brackish water desalination plants.

Post a Comment for "Ro Plant Design Calculation Excel"